Sparring about your Lean issue?

Call René

CASE STUDY - Thanks to Lean Thinking, this Spanish construction company was able to deliver a challenging project within a year, well ahead of schedule. Here's how they did it.

Words: Jorge Mercader, Lean Coach, and Marc Llopis, Production Manager, Constraula

In recent years, construction sites have sprung up all over Barcelona's up-and-coming Poblenou neighborhood, changing it beyond recognition. One of these construction sites, however, has a great story to tell. A new 7-story residential building has just been completed. Funded by the city government, the project aims to provide affordable housing in a neighborhood where the average price of an apartment is €4,500 per square meter.

The project began in October 2022. We had until February 2024 to complete it, but we finished ahead of schedule - a year after it started. This despite a few hiccups in the initial phases, when City Hall made some changes to the original project.

The special feature of the building is that it is made of wood - not common in this part of the world, but an increasingly popular solution. Constraula, the city maintenance and city services company of the Sorigué Group, won the tender largely because their project involved the use of this material, by far the most sustainable you can use in construction (the building even won the Construmat sustainability award this year). It was our first project of this kind, but through research and careful selection of suppliers, we were able to make up for what we didn't know.

This was also our first lean experience. Last year, we decided to attend a few lean-training sessions (these were based on real life, using a construction simulation with LEGO bricks). We liked those so much that we decided to try out the approach. And what better way to test it than to use it in a soon-to-be-launched project? From day one, the team showed great enthusiasm and that was ultimately the reason for our success.

Of course, we relied heavily on Last Planner, the main planning tool in a construction project, which promotes collaboration and facilitates the elimination of waste. To that we added other lean techniques, such as 5S, daily management and scientific problem solving.

What lean brought us was collaboration between people and all the different subcontractors. Everyone was involved in the initial planning of the construction project and attended follow-up meetings week after week. We quickly found out that with lean you can discover problems earlier and identify all the interdependencies that - if ignored - can lead to major problems and significant delays in the delivery of the project. The beauty of a systematic approach to discovering, analyzing and solving problems was that if we encountered problems on the second floor, we already knew that we were likely to encounter them on the other floors as well. This made us better prepared to deal with them because we used kaizen to make all the necessary improvements and prevent problems from recurring.

The place where problems were raised and discussed was our weekly meeting, where we reflected on what had happened the previous week, the problems we encountered (as well as how many tasks were and were not completed) and looked ahead to the next week.

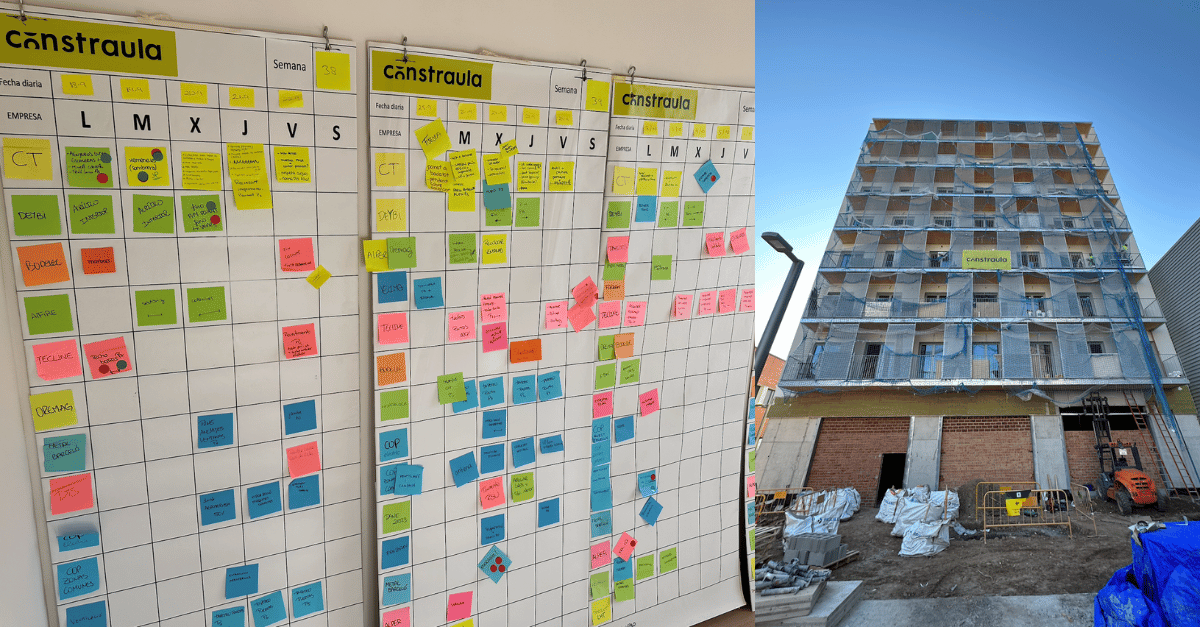

Our guide in all of this was the Master Plan. To design the process and determine the proper sequence of activities, we first worked with the project's core team, including the site manager, supervisor and production manager. We made estimates based on our experience and knowledge of what each of these processes would entail. Then we put the plan on a big board and discussed it with our industrial partners. This took three or four sessions. It's important to invest time up front to figure out the process and sequence so you don't have to do it "along the way" and probably have time-consuming and wasteful re-planning.

In addition to our Master Plan sign, we had four others - the "look ahead signs" - that covered the next four weeks. They highlighted the most important tasks to be accomplished and indicated by which merchant/company and by what date they were to be completed. The look-ahead signs gave us a very clear representation of the order of work, day by day, telling everyone what they needed to do and when. Lean visual management made for very smooth communication throughout the process.

As for performance indicators, we focused on the essential ones and avoided unnecessary complexity. We primarily tracked two: the attendance of industrial partners at our meetings and the completion rate of weekly tasks. Our tracking tools were simple Excel spreadsheets. Each week we assessed the completion rate of scheduled tasks. When tasks were not completed, we performed a detailed analysis of the root causes so we could address them and fix the problem.

For this project, we had 13 craftsmen - our "suppliers," so to speak. Of course, they weren't all working on the building at the same time, but that didn't make coordination any easier. Fortunately, we had our lean system, which allowed us to create that coordination and suggest the correct order in which each task should be done, so that the next subcontractor could come in and do their part without any obstacles. To further support the work of the subcontractors, we also applied 5S to maintain order and cleanliness on the construction site: that way, each craftsman could work in the best possible conditions.

In addition to our master plan and weekly schedule, we also had to manage our daily activities. Whenever unforeseen factors, such as weather, appeared and threatened to impede our work, potentially putting us behind our schedule, we tried to think creatively and look for a quick solution. For example, devoting resources to another task that, although not ideally timed, could still be accomplished without disrupting the overall order of work.

This project reminded us how important good planning and coordination are in construction. The fact that communication was seamless and that we recognized the benefits of working with the work of others in mind made it possible to solve virtually every problem we encountered. When the subcontractor responsible for the thermal insulation of the facade told us that they would not have enough people available to complete the job on time, we immediately contacted the architect and determined that we could still install the windows and ask the subcontractor to come later for the finishing touches. This countermeasure may not be the most common way of working, but it allowed us to not interrupt the work and stay on schedule. Another example of successful coordination was the work we did to organize the delivery of wood all the way from Austria: we spoke early with the supplier and knew exactly in what order the trucks would arrive and which modules they would carry. Based on this experience, in the future we will try to cooperate only with subcontractors and suppliers who are willing to adapt to our way of working.

Wooden structures are faster to put together and allow you to do several tasks at once, and that is certainly one of the reasons behind our early delivery. But we have no doubt that Lean Thinking is the other reason: it showed us how to break down the work into small pieces that were easier to oversee and manage, and it ultimately allowed us to work with subcontractors as one team. It was incredible to see the synergies that emerged during the weekly meetings, where different players used their experience to help each other and discuss the best way forward.

To complement our work to optimize processes, we also put a lot of emphasis on the people who make up the broader project team. From day one, we looked for agreement among the different players, set clear goals and expectations, and defined our values, defining how we wanted to work and manage things. For us, it was important to create accountability to ensure that everyone was aware of how their timeliness positively affected the work of other subcontractors and the progress of the entire project.

It's clear to us that Lean thinking has benefits for everyone involved, and we think our subcontractors realized that too. Knowing exactly what to do and when to do it allowed them to use their resources smartly and made everyone's job easier - proven by the fact that there was no stress on our construction site and we always felt in control of the situation. This speaks volumes about the value of Lean Thinking in construction, something so obvious to us that we are determined to use the methodology in all our future projects. We wouldn't know how to go back to how it was!

THE AUTHORS

Sign up for our newsletter