Sparring about your Lean issue?

Call René

Lean is a way of improving processes. The goal is to help customers as well as possible at the lowest possible effort and cost. Of course, you are also a customer and you want to be helped in the best possible way, whether in the hospital, in the supermarket or if you order something online. With Lean, you look at how to deliver your service or product to your customer in the smartest way possible, in the shortest time possible. When we talk about Lean, we often talk about the different Lean principles, Lean methods and Lean techniques with which you can improve processes and thus your work. We explain more about it in this article.

Lean originated in the Japanese automotive industry (Toyota), but has also been successfully applied for decades in a variety of organizations in the Netherlands.

Lean helps hospitals, nursing homes, municipalities and those kinds of organizations to do their jobs the best they can, within the available budget they have. And it helps commercial companies develop smart products and services so they can be profitable and get people to work.

The beauty of Lean is that you can learn how to do your own process improvements and make your own job as enjoyable as possible, without having to perform all kinds of unnecessary work. Want to know if Lean working is applicable in your type of work? At the end of this article we will give you some tools to answer this question. Want to know which issues in which industries we improve with Lean? Then take a look around at our industry pages, where we outline several example cases in various industries.

In short, Lean is a collective name for a set of Lean principles, ideas, Lean methods and Lean techniques aimed at realizing maximum value for the customer with minimal use of resources and people. The focus is on improving processes to reduce lead time, increase quality and delivery reliability and reduce costs.

Customer value basically means: what does your customer find valuable and is your customer willing to pay an appropriate price for it. It is wise to talk to customers about what they find valuable about your product and/or service. If your product or service helps a customer and solves his or her problem, then your organization has a right to exist. Your organization probably wouldn't exist if no one found your products or services valuable and wanted to spend money on them. Within Lean, customer value is an important concept: it looks at all the steps in a process and asks the question: does this step add value (is this a value-adding or value-creating activity?) for our customers or not? If the answer is no, then the next question is: can we skip or eliminate this step? And what do we need to do that?

Determining customer value is not always so easy, because customers often value different things, or it depends on the situation. But by asking the question you get a better understanding of which steps in a process are valuable to the customer and which steps are not. Customer value is also expressed in SQDC or Safety, Quality, Delivery and Cost. Customers want a safe product, of a certain quality, at a certain time and for an appropriate price. This helps to see more precisely what is a valuable step or not, or what you need to work on to create more or better customer value.

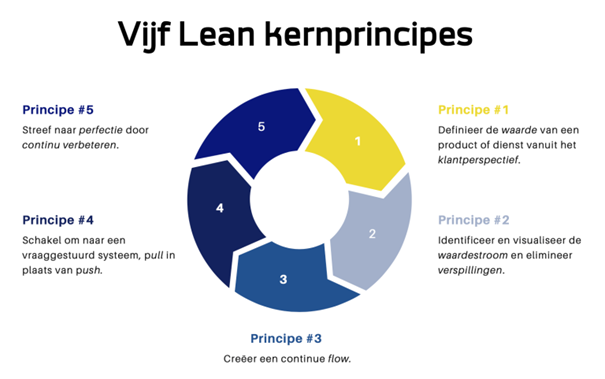

Value is therefore the first principle of the five Lean principles, which we explain later.

The purpose of Lean is not primarily to cut costs. Rather, the challenge within Lean is how to deliver as much customer value as possible for as little use of resources, time, energy and effort as possible. These resources can then be used to create customer value in other areas. Often, Lean does deliver cost savings, but that is a nice extra benefit. It is therefore about having as little waste as possible in the process. We will now explain this concept.

If you're going to apply the Lean method to improving processes or your work, you're going to look for as many wastes as possible in the process or in your daily work. And you're going to try to eliminate these wastes. Wastes don't add anything for your customer: the customer is actually not willing to pay for these activities within the process. They don't add anything for the customer and therefore often not for your organization either. After all, waste always costs time (and money). Wastes are also called non-value-creating activities.

So if you want to start improving a process, you always look for the value-creating activities and the non-value-creating activities. And then you look at how you can eliminate those non-value-creating activities, combine them with other activities, do them at a different time or make them simpler.

Toyota originally named seven wastes that often occur in their processes. You can use these to take a focused look at various non-value-added activities. Read more about Lean's 7 wastes here .

Daniel (Dan) Jones and James P. (Jim) Womack are the founders of Lean and developed a Lean management theory that revolves around five Lean principles. More on this in the book Lean Thinking. The five Lean principles guide organizations in any industry that employ Lean as a method for continuous improvement.

A lot! The beauty of Lean is that you can start applying it both very big and very small. Of course, the answer to this question depends on your personal situation, but we try to give you some guidance here.

Besides training, we also help organizations in consulting projects where we help teams or companies to tackle their challenges in a Lean way. Take a look at our advice page and read more about the issues we have tackled in various industries. Here you will find various cases and articles explaining how we have helped clients and what the results were.

We are always willing to take a moment to spar with you about your Lean question! Feel free to contact us!

Sign up for our newsletter