Sparring about your Lean issue?

Call René

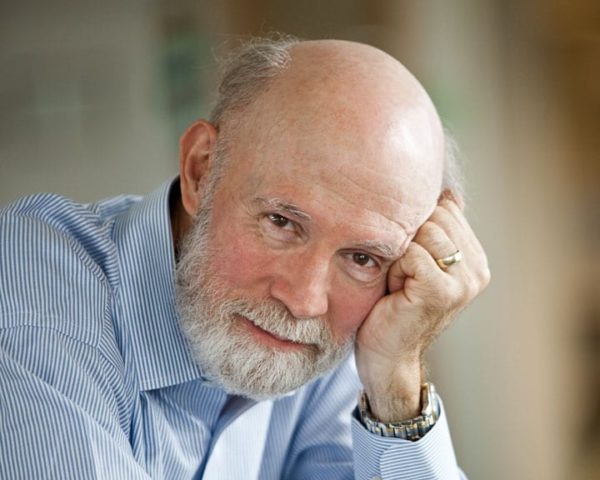

Every Lean generation has faced challenges, and it is essential that we understand the context around us if we are to continue to grow our community, says Jim Womack.

All ideas face generational challenges as knowledge increases with experience and the outside world changes. Habituation effects and boredom with ideas are real. So it is necessary to reinvigorate the message in each generation based on sustainable basic ideas. Lean Thinking is no different and we are grappling today with the next generational change, the fifth in the long history of Lean for nearly a century.

The founding generation was a long one through the work of a father(Sakichi Toyoda, who in the 1920s brought in the idea of jidoka for his textile looms) and his son Kiichiro Toyoda (who in the 1930s brought in the idea of just-in-time to manage the flow of materials and information from the beginning of production to the end). These eventually became the two pillars of the Toyota TPS house. However, due to the chaos in the world - the Great Depression and World War II - the founding generation found it difficult to go beyond theory and actually build the house before handing over the challenge of implementation to the next generation at the time of Toyota's financial crisis in 1950. (Kiichiro then stepped down as CEO to take the blame for the need to lay off a third of the workforce to survive Japan's sudden depression.)

After Toyota's crisis, the ideas were picked up by the second generation for elaboration and application within Toyota - Taiichi Ohno(TPS in manufacturing), Kenya Nakamura (the product and process development system), Shotaro Kamiya (the distribution and customer support system), and Eji Toyoda (the self-effacing genius who worked behind the scenes on the lean management system). They created a complete business system by the early 1970s, when Toyota's ideas suddenly became significant to the world because of Toyota's superior performance during the energy and economic shocks of that era. Toyota began a rapid global expansion to eventually become the largest automotive company.

The next generation, beginning in the late 1960s, conceived what might be called the Toyota "missionary society" in the form of the Operations Management Consulting Division, eventually headed by Fujio Cho, to quickly spread Toyota's ideas through the supply chain and its growing operations around the world. (This work continues to this day within Toyota in the Operations Management Development Division and externally through Toyota TSSC in North America and by organizational units with other names in other regions.)

And then there is the long fourth generation of independent missionaries, starting with the NPS (New Production System) and Shingijitsu consultants in the 1980s, when they emerged from OMCD's Lean crusade within Toyota Group companies. These efforts continued into the 2010s and expanded into the educational initiatives of the Lean Enterprise Institute (starting in 1997) and the 30 other member organizations in the Lean Global Network.

In the fourth generation, Lean ideas were applied to virtually every activity (manufacturing, product and process development, supplier management, customer support, general management) in virtually every industry, in virtually every country, with extraordinary zeal and with many dramatic examples of Lean leaps to higher levels of performance in specific activities. But no new "Toyotas" were created, with a completely lean business system, and the results of isolated leaps were difficult to sustain. (I just visited a company in Europe that was in the process of cellularizing a manufacturing process for a complex industrial part that it had cellularized 30 years earlier, in the late 1980s, using identical Lean methods, before losing the knowledge completely and returning to traditional mass production.)

This long chain of generations now spans more than 90 years, and it is daunting to consider that we have only just begun. Moreover, the world has changed in important ways, creating new challenges as the fourth generation nears its end. But let's not waver: our ideas still work! They are the best known way to create more value with fewer resources by creating stability and removing waste while creating satisfying work in communities of lean practices. So it is really urgent to think about the important work of the fifth generation now emerging as we look beyond the pandemic.

The first element in A3 thinking about a problem is understanding the current situation, so let me fill in the first box at the top left of an A3 (titled "Moving Lean Forward") by describing the situation as I see it at the beginning of the next era of Lean thinking.

Perhaps the most important background condition is that while our community was busy promoting Lean Thinking, modern management - fully developed in the 1920s at General Motors before Toyota really took off and elaborated in the era of Jack Welch at General Electric - proved remarkably robust. It is a hardy perennial, replacing traditional management systems dating back to the Pharaohs, easy to plant and able to survive many attempts at extinction - Theory Y, Total Quality Management, Six Sigma, Business Process Reengineering, team-based management - as well as wars, depressions and pandemics! And it is taught today, mostly implicitly, in business schools and employee development programs in companies around the world. Making a frontal assault, as many Lean practitioners in earlier generations attempted, has proven extremely difficult. We found a number of leaders of modern management organizations who were able to change their fundamental thinking and management styles to implement Lean management, but it was difficult to sustain their success when leadership was transferred to the next CEO or when the company was sold.

Part of the financial success of modern management in recent decades has been a willingness to ignore the current workforce and outsource or offshore a growing portion of value creation to low-wage areas to cope with growing cost competition. (These practices were facilitated by financial systems that confused narrowly defined cost savings with lower total costs.) So the need diminished to seriously consider new management practices that could create more value in existing organizations and develop the competence of each employee. (Remember that Toyota has always taken the position that it will defend the career paths of its permanent employees over a 30-year working life. So the company had no choice but to constantly create new capabilities in its existing employees through Lean Thinking. This always fosters the stability within organizations that makes this approach possible and effective).

Moreover, the steady advent of new process and information technologies has raised hopes for productivity and quality improvements that do not require employers to manage their employees differently. Industry 4.0 is still largely a slogan with no demonstrated benefits, but its prospect makes managers hesitant to try to change fundamental work processes and management methods.

Finally, the world's perception of value-creating work has changed. When Lean Thinking took hold in the 1920s, the prototypical human activity was the production line with tightly coupled work sequences of highly repetitive tasks in huge facilities. Today, after years of advances in information technologies and a shift from an industrial to a service economy, the prototypical activity has become the seemingly self-directed work team developing a software module in virtual environments, often replacing traditional manual labor in other activities. Although the original ideas for scrum and agile were derived directly from Lean Thinking, this fact is often lost in the post-industrial economy where knowledge work managers often don't know what they don't know.

On the other hand, these resources are now largely exhausted. The global pool of cheap labor is no longer growing, but political resistance to cross-border labor arbitrage is. Indeed, much of the political turmoil of recent years in developed economies can be traced to wage stagnation or even decline among front-line value creators who seek better distribution of the spoils and greater respect for their work. Employers will be forced to take these trends into account.

Moreover, work reorganized in the information age proves far from satisfying for most workers, who feel the loss of community and sense of mutual obligation that are central to Lean Thinking. Hence the great resignation and general malaise about work in the world.

Looking ahead, I believe there will be real opportunities in the next generation to advance the cause of Lean Thinking to address these challenges. Lean is also a hardy perennial! But these opportunities will have to be actively seized if the fifth generation of Lean thinkers is not to be the last. This is the collective work of the Lean Community to fill in and act on the rest of the A3.

Sign up for our newsletter