Sparring about your Lean issue?

Call René

By building Lean Thinking into its processes and culture and developing people's capabilities, this Norwegian company serving the oil and gas sector has achieved fantastic results.

Beerenberg is a Norwegian service provider for the oil and gas sector. It supports new construction, modification and maintenance projects in a range of activities, including Insulation, Scaffolding and Surface Treatment (ISS) as well as passive fire protection, technical cleaning, rope access and construction/outfit services and mobile machining/cold cutting. The company provides design and engineering services to some of the largest offshore operators in the North Sea.

Founded more than 40 years ago, Beerenberg has grown into a successful company. When the oil & gas industry stalled in 2014-2015, the company looked to Lean Thinking as a way to remain profitable in uncertain times. At that time, the oil industry had become accustomed to high costs and high prices; this was about to change dramatically. A sudden drop in oil prices by nearly 50% left the industry looking for ways to deliver better quality at lower costs. Beerenberg's senior management team embarked on a Lean transformation that would usher in a long learning journey based on the principle of genchi genbutsu - a Japanese expression that translates to "going to the real place" to see for themselves, gather facts and make correct decisions by consensus.

In those early days, the management team realized that the organization had grown accustomed to the heady days of "name your price" projects of increasing complexity, scope and cost. They saw little in knowledge sharing, standardized work, or visual and understandable engineering checklists, leaving them alarmingly dependent on the whims of the experts in the organization (at the time, the labor market in the industry was understaffed, with many often changing jobs in search of higher wages). While this lent itself to building personal capabilities and learning, it was not great for yokotes - sharing learning across the company. In the classic words of Taiichi Ohno:

"Where there is no standard, there can be no improvements."

With nearly 1,000 employees, the management team knew they had a mountain to climb and that the only way to climb it would be to give everyone a chance to succeed. The mountain metaphor is particularly apt here: Bearenberg is also the name of a 2,277-meter-high volcano that dominates the Norwegian island of Jan Mayen, in the Arctic Ocean. Top management set the bar high and was determined to develop "mountaineering" skills in everyone so that everyone could climb their own Beerenberg of improvements. In the true spirit of Toyota and other successful lean organizations, they decided early on that they wanted to develop their own understanding of lean through trial and error, building their own skills and competence, rather than buying a ready-made lean program from outside consultants. Their goal was to become a learning organization that would be the best ISS provider in the Norwegian industry.

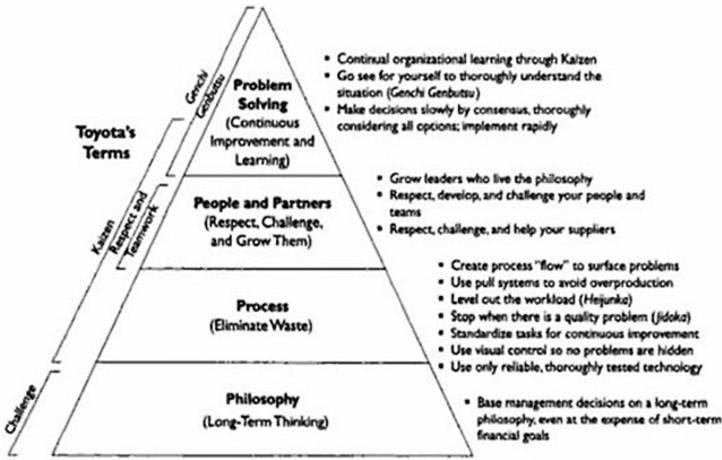

To identify and better understand the challenge they faced, Beerenberg began by surveying their current circumstances in terms of lean practices. They went to the gemba and studied the work and, based on the 4P model described by Jeffrey Liker in The Toyota Way, measured themselves on their application of the 14 principles. Now each department conducts this exercise annually as a self-reflection, to assess their level of "lean".

By the fall of 2015, Beerenberg had already developed a training program and started training their own internal Lean coaches. They call them Lean navigators. To identify potential candidates, the organization first asked if people would volunteer to join. At that point, they didn't know how employees would respond, but they were pleased that a large number of people came forward. In the end, 10 navigators were identified and trained who could cover the entire company, both offshore on the oil rigs and onshore in support functions. The Lean navigators were charged with supporting the line organization with Lean thinking, principles, tools and methods - but without taking responsibility for improvements away from leadership, supported by operators. All the way from the senior leadership team, down to middle managers and team leaders.

In the first half of 2016, the focus of the senior management team and their growing group of Lean navigators was on training the rest of the organization in the use of visual management tools (from 5S and to daily management obeyas), kaizen and quality tools (such as 5 Why's, VSM, fishbone diagrams), as well as PDCA thinking through A3s. They also supported front-line staff in developing standard operating procedures to lay a foundation for kaizen. It may sound like this is what happened, but Beerenberg actually stayed true to Ishikawa's emphasis on "training subordinates" in his version of PDCA, with the goal of making it reach everyone and building a sustainable improvement culture. Therefore, these training activities, which began in 2016 and 2017, are still ongoing.

Instead of moving on to the next best practice to implement, Beerenberg continued their training and improvement work throughout 2018 and 2019 to develop a more mature organization. Building competency in both leaders and employees by deepening the Lean tools, Lean methods and way of thinking. Instead of simply scrapping improvement initiatives that had not worked immediately, they adapted and conducted new experiments based on what they had learned from their failed attempt. One example was how they experimented with different methods and approaches to plan their projects.

It was around this time that the organization began to introduce some of the basic Lean tools into offshore operations. The team there wondered what was going on in the onshore offices, where people were celebrating their A3s and constantly talking about Lean .

Steinar Fjellhaugen, one of the original Lean navigators, proved to be the right man to bring Lean Thinking offshore. By supporting very practical pilot improvement projects, he was able to show how Lean thinking and tools could create win-win situations by making work safer (always the priority) and easier - resulting in fewer mistakes, less hassle, better quality and lower costs. One of the improvements made offshore was 5Sing the spray booths. They also created standardized and personalized equipment work bags, allowing each operator to gather all the tools needed to get a job done quickly. Usually, operators and teams sat over the radio with each other to request equipment and tools, but the personal work bags eliminated the need for this coordination and rescheduling on site.

Another interesting suggestion was to talk about the work in a different way at the planning stage. An offshore installation has many pipes and fittings, and not all of those pipes and fittings need to be surface treated at the same time. Previously, they spent a lot of time discussing all the installations they would not treat, the ones that were not part of a particular work. But often they ended up treating those anyway. So they began discussing the piping and fixtures that did need to be handled. As simple as it sounds, this shift had an amazingly positive effect on quality and almost completely eliminated the problem of working on the wrong pipes and fixtures.

Running ISS operations offshore is very different from building cars, as people throughout the organization often reminded the Lean navigators to express their resistance. Inspired by manufacturing companies, Beerenberg decided they needed to create their own Lean game and training dojos to demonstrate what the basic TPS principles of just-in-time, jidoka, basic stability and employee engagement looked like in ISS operations. At their site in Kokstad, just outside Bergen, they built a mini-rig where people can Lean training by performing the same value-added tasks that they or their colleagues will then perform offshore. This dojo has played a big role in training operators and support staff and has helped them better understand both Lean and the work Beerenberg does for its customers. They have even built a smaller dojo to bring offshore.

Beerenberg's management team assumed it would take some time to see the results of their initial activities and were willing to be patient. By the end of 2016, however, there were already signs that the changes were having a positive impact where it really mattered. Commercial customer feedback saw a 63% improvement in contractual KPIs and a 43% productivity improvement in scaffolding operations. HSE-related incidents were reduced by 40%. It was no longer necessary to make the business case for Lean . These early results served as great inspiration and were used to spread Lean further across the organization, with the help of the Lean navigators. What was their formula for success? Training, training, training and something they call the "SA meeting."

The purpose of SA meetings is, in lean terms, hansei (reflection) and yokoten (knowledge sharing), to carve out time for discoveries, discussions about completed and ongoing improvement activities. Lessons learned, success stories and failures are regularly shared throughout the organization.

From the beginning of 2016, regular "SA meetings" were held. In the beginning, Lean navigators held monthly meetings with a regular cadence, attended primarily by the team and line managers, presenting various improvement A3s and reflecting on and learning from A3s from across the organization. This monthly meeting is still ongoing, and project managers across the company have now incorporated the idea of the SA meeting into the projects they lead. These projects often have a one-year cycle, especially the maintenance projects, and the effect of involving the various functions and departments involved in a cross-functional reflection has been profound. People gain a better understanding of the complexity of their work. For example, it was discovered that the process of purchasing the right type and quantity of pipes, flanges and valves involved about 15-20 different steps - something no one was aware of before people started using Lean tools to visualize and study the actual work. Now the lead time has been cut in half, from the time the need is identified to the time the right material is delivered offshore. They have also managed to do the same with documentation, detailed work packages and estimates.

The success of these initiatives in operations led Beerenberg to expand the development of Lean coaches and systems to the entire company. Today, the organization's delivery system is driven by visual management, daily dailies and standardized work. For Beerenberg employees and managers, however, this is just the end of the beginning. To stay ahead of their competitors and continue to delight customers by delivering high-quality work. The real work of sustaining a learning organization, one that can deliver Beyond Expectations - the name given to the company's Lean transformation - begins now: the ongoing development of people, one at a time, by finding and solving customer problems, one at a time, with the goal of creating a culture of problem solving where everyone is constantly concerned about quality. For Beerenberg, Lean is a strategy.

Sign up for our newsletter